The history and evolution of custom basketball jerseys in the sport

|

|

Tiempo de lectura 12 min

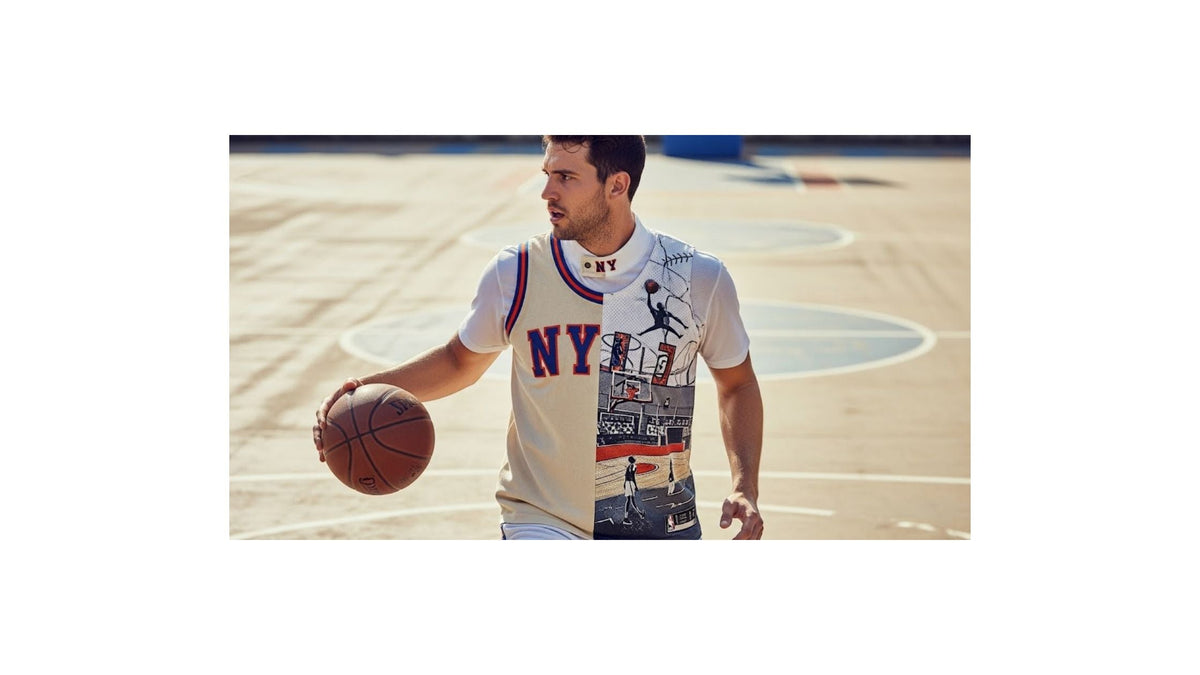

The story of custom basketball jerseys is really a story about identity, technology, and culture intersecting on the hardwood. From wool and flannel to moisture-wicking mesh, every era left its stitch on the game’s look and feel. Today, custom basketball jerseys express local culture, team heritage, and performance science all at once, while empowering teams at every level to create their own uniform language.

What were basketball jerseys originally made of?

Custom basketball jerseys trace their roots to utilitarian beginnings, where early basketball was played in everyday attire such as flannel trousers, sweaters, and long skirts for women, before teams gradually adopted wool and cotton uniforms in the early 1900s. An A.G. Spalding & Brothers 1901 catalog featured padded shorts and form-fitting jerseys, while by 1903 Spalding even marketed specialized shoes with suction-cup soles for grip, signaling the first shift from streetwear to purpose-built basketball gear.

Through the 1920s, uniforms became more functional: sleeveless jerseys and mid-length shorts replaced long sleeves and pants to improve mobility. Teams added letters and insignias for identification and pride, anchoring the visual identity that would later blossom into full team branding. Women’s uniforms evolved too, with knee-length bloomers and short sleeves reflecting both practicality and social norms of the time.

Wool and cotton dominated until synthetic fibers like nylon arrived in the 1930s, transforming sportswear with lighter, more durable, and easier-to-launder materials. Nylon-polyester blends began appearing in basketball uniforms by the late 1930s, ushering in a standard for breathable and stretchable athletic apparel that would influence decades of design.

How did custom basketball jerseys evolve from wool to performance mesh?

Custom basketball jerseys moved from heavy natural fibers to engineered polyester blends as the sport accelerated in pace and visibility. By the 1940s and 1950s, blended synthetics enabled shorter shorts, tighter sleeveless jerseys, and clearer differentiation between teams, especially as the BAA and NBL merged to form the NBA in 1949. Uniform numbering grew widespread in the 1950s, while iconic influences like the Harlem Globetrotters’ flamboyant uniforms tied performance to showmanship.

In the 1960s and 1970s, design became bolder more adventurous color palettes and imaginative patterns before the simpler, more streamlined looks of the 1980s and early 1990s. Those decades still produced classics: think Chicago’s black pinstripe alternate era as a symbol of brand power in the Michael Jordan years. By the 2000s and 2010s, supplier eras, Champion, Reebok, Adidas, then Nike brought new fabric innovations and consistent league-wide standards for fit and technology.

Today, polyester micro-mesh, four-way stretch knits, and sweat-wicking technologies define performance. Sublimation printing enables complex graphics without adding weight, while reversible builds and tailored fits deliver versatility and comfort. These advancements allow teams to push aesthetics without sacrificing breathability, durability, or freedom of movement.

Custom basketball jerseys: Which milestones shaped the modern uniform?

Custom basketball jerseys reflect a series of breakthroughs. The first was standardization numbers, colors, and logos bringing clarity to gameplay and identity. The second was materials, synthetics replacing wool making uniforms lighter and more resilient. The third was mass customization delivered by digital design and on-demand production, which democratized pro-level creativity for schools, clubs, and rec leagues.

Supplier eras accelerated these shifts at the pro level. Champion’s tenure in the 1990s coincided with the globalization of NBA culture. Reebok followed, then Adidas standardized across all NBA teams through 2017, before Nike returned to introduce new design programs and special patches, underscoring the jersey’s role as both performance gear and cultural canvas. That cadence of suppliers mapped directly to evolving materials, fit, and graphic sophistication on court.

Special edition programs cemented the jersey as culture. City-inspired collections connected teams with neighborhoods and heritage, introduced local symbols and colorways, and turned every season into an anticipated reveal cycle for fans and collectors. This widened the meaning of “custom” beyond pro locker rooms to community identity and storytelling at every level of play.

Era-by-era evolution at a glance

Era |

Materials |

Style and features |

Notable shifts |

1890s–1910s |

Wool, cotton |

Street attire to wool uniforms; padded shorts; early jerseys |

Functional transition begins; Spalding catalogs; specialized shoes emerge |

1920s–1930s |

Wool to nylon blends |

Sleeveless tops, mid-length shorts; insignias and letters |

Greater mobility; synthetic fibers begin to replace heavy naturals |

1940s–1950s |

Nylon-poly blends |

Shorter shorts, tight jerseys; widespread numbering |

NBA forms; clearer team differentiation; Globetrotters’ showmanship |

1960s–1970s |

Synthetic knits |

Bold colors, adventurous patterns |

Visual experimentation; cultural flair |

1980s–1990s |

Lightweight synthetics |

Streamlined looks; iconic alternates (e.g., pinstripes) |

Brand-forward era; supplier consolidation begins |

2000s–2010s |

Performance meshes |

League-wide standardization; supplier eras |

Pro-level tech; special editions expand storytelling |

2020s |

Advanced poly, 4-way stretch |

Sublimation, tailored fits, reversible options |

High customization for all levels; digital design tools |

How custom basketball uniforms are made today

Modern custom basketball uniforms begin with digital design. Teams and organizations visualize concepts in 3D configurators, customizing colors, logos, fonts, and patterns down to gradients and micro-details. This front-end experience reduces guesswork, helps align stakeholders, and speeds approvals, so production can start with confidence in the final look.

Sublimation is the dominant printing method for intricate, all-over designs. The process infuses dye into performance fabrics, ensuring colors won’t crack or peel and preserving breathability. For certain aesthetics, manufacturers blend sublimation with embroidery, screen print, or woven patches, balancing weight, durability, and cost while matching brand guidelines or league rules.

Suppliers now offer reversibles, cut-and-sew variants, and tailored fits for men’s, women’s, and youth teams. Features like mesh ventilation, moisture-wicking finishes, and stretch panels enhance comfort. Turnaround times have shortened dramatically, with reputable providers offering delivery windows of roughly two to three weeks for team orders, depending on design complexity and rush options.

Techniques, pros, and best use cases

Method |

What it is |

Why teams choose it |

Best for |

Sublimation |

Dye infused into fabric |

Lightweight, vivid, durable graphics |

Complex designs, gradients, all-over patterns |

Cut-and-sew |

Panels stitched from colored fabrics |

Structured look, color blocking, reinforcement |

Classic aesthetics, robust construction |

Embroidery/patch |

Threaded or applied logos |

Premium texture and depth |

Logos, commemorative marks, sponsor badges |

What makes a great custom jersey design?

A strong concept ties team identity to legibility and performance. Contrast between base color and typography ensures names and numbers pop under arena lights. Thoughtful placement of accents side panels, piping, shoulder yokes adds personality without cluttering readability, while heritage cues connect past and present in a way fans immediately recognize.

Material choice and fit determine how design feels on the body. Four-way stretch knits reduce restriction, while hydrophilic or moisture-wicking finishes manage sweat over four quarters. Reversible builds multiply utility for practice and tournaments, keeping sets cohesive and cost-effective for clubs and school programs that cycle through multiple color matchups each week.

Production factors influence outcomes. Sublimation thrives on vector graphics and high-resolution art; embroidery requires simplified marks to keep stitch counts manageable. Teams that plan artwork and roster data early avoid bottlenecks, especially when coordinating youth, women’s, and men’s cuts across full programs. Modern platforms streamline those logistics from design to door.

How pro influences shaped custom design

The NBA’s supplier timeline created global templates for cut, materials, and creative direction. Champion’s era paralleled the league’s rise to international prominence; Reebok and Adidas scaled uniform programs across all teams, and Nike’s current tenure pairs innovation with cultural storytelling, including notable patches and special-edition executions. Each era normalized tech and style that quickly filtered to colleges, high schools, and clubs.

City-inspired jerseys reinforced that uniforms are canvases for place-based narratives. Elements borrowed from transit systems, local typography, or civic symbols injected civic pride into on-court visuals and broadened what “team colors” could mean. As fans embraced these stories, community-driven customization surged across grassroots basketball, with teams designing graphics that reflect neighborhood histories and school traditions.

Legacy aesthetics remain a north star. Celtics green and shamrocks, Lakers purple and gold, Bulls pinstripes all stand as evergreen reminders that great uniforms earn timelessness by marrying clarity, symbolism, and context. Custom work that nods to these elements, without copying them, taps into the same visual language that makes fans feel at home the moment a team steps on court.

Ordering and logistics in the age of digital design

Teams increasingly expect pro-grade configurators and transparent pricing, so selection, visualization, and checkout can happen in one flow. Platforms supporting full-color freedom, vector art uploads, and name/number data imports have become the baseline, with proofs and approvals built into the workflow. That integration reduces rework and keeps production on schedule.

For program directors, coordination across varsity, JV, and youth demands consistency. Offering the same template in men’s, women’s, and youth cuts safeguards brand integrity. Providers that carry matching shorts, shooting shirts, and travel apparel enable a unified look from warm-up to off-court travel, extending identity beyond game night and into social content and community events.

Turnaround and budget play together. Sublimation often delivers the best value for complex art and bulk orders, while combining embellishment methods can target premium moments, like anniversary crests or rivalry games. Many reputable suppliers cite standard two-to-three-week windows for delivery, with rush options available during peak season scheduling.

Ethical, durable, and future-ready

Durability matters for sustainability as much as performance. Long-lasting colors, resilient stitching, and consistent fit translate to extended life cycles, fewer reorders, and better budget stewardship. When teams invest in robust construction and timeless design, they reduce waste while keeping rosters uniform across multi-year cycles.

Responsible production and scalable reorders help clubs handle growth and attrition. Maintaining digital patterns and Pantone-matched palettes ensures that mid-season adds or next-year expansions feel seamless. As technology improves—think recycled polyester, smarter moisture management, or even embedded identifiers custom jerseys will keep blending performance with purpose in more sustainable ways.

Teams also benefit from coordinating their jerseys within broader wardrobes warm-ups, hoodies, and travel gear to create a cohesive brand ecosystem. That consistency pays off in fan merchandise, photography, and recruiting, where look and feel become differentiators as real as playbooks and practice time.

The cultural lens: why it all matters

Uniforms are storytelling devices. They authenticate a team’s identity while giving fans symbols to rally around. The move from wool to nylon to engineered mesh mirrors basketball’s own journey from a local pastime to a global spectacle, where aesthetics and performance carry equal weight. Custom basketball uniforms extend that story to every court, school gyms, parks, youth tournaments so more players can feel like they belong in something bigger than themselves.

In the end, a great jersey turns moments into memories. Colors and typography become shorthand for last-second shots, buzzer-beaters, championship runs, and community pride. That’s why, even with infinite digital possibilities, the best custom jerseys stay grounded in legibility, heritage, and function so the story they tell remains clear for years to come.

Mid-season upgrades and program refreshes

Teams often refresh elements mid-season or between tournament windows, using compatible templates to preserve continuity. Reversible practice sets and alternate shorts keep budgets tight while providing fresh looks, and sublimated updates can carry commemorative marks without disrupting base design. Flexible production pipelines make these smart tweaks practical without sacrificing identity.

Clubs scaling across age groups gain leverage by standardizing core motifs—striping, fonts, and colorways—while allowing subtle variation by level. That balance lets younger teams aspire upward while varsity keeps an elite edge. With high-quality 3D tools, directors can preview those variations, minimizing surprises when boxes arrive at the gym.

Programs aiming to stand out beyond game night incorporate coordinated off-court pieces travel polos, jackets, and hoodies that reinforce brand cohesion. These touchpoints amplify a team’s presence in media days, tournament arrivals, and social content, elevating the overall perception of the program’s professionalism.

A note on broader gear ecosystems

Uniforms live within an ecosystem of practice gear, accessories, and fan merchandise. Providers that offer consistent materials and shades across jerseys, shorts, and warm-ups make it easier to keep rosters looking aligned. For organizations building community, extending the identity to supporters parents, alumni, and local fans multiplies impact and unlocks new traditions around game day attire.

Programs seeking long-term identity should capture a brand kit that includes color codes, typography standards, logo spacing rules, and placement guidelines for names and numbers. This ensures every reorder, alternate, or special edition sits comfortably within the team’s visual language, protecting legacy and ensuring recognizability season after season.

As customization gets more sophisticated, rosters can lean into meaningful narratives local landmarks, school mottos, historic seasons while retaining performance-first construction. The most successful programs approach uniforms as an ongoing brand narrative rather than a one-off purchase, and that mindset pays off on the scoreboard of perception.

Putting it all together for teams today

Teams designing custom jerseys basketball programs will rely on digital visualization, smart material choices, and production partners fluent in both branding and athletics. When concept, craft, and logistics align, uniforms become a competitive advantage: players move better, fans connect deeper, and programs look unmistakably themselves from tip-off to travel. For directors and coaches, the right process keeps focus where it belongs on development and execution while the jerseys do their quiet work of amplifying belief.

Organizations modernizing their look should aim for versatile color stories, legible type, and durable construction that can live across home, away, and alternate sets. Sublimation unlocks expressive graphics without weight; cut-and-sew adds architectural structure when desired. In either case, consistency across sizes and cuts ensures the whole program feels unified on and off the court.

Teams evaluating suppliers will weigh 3D design tools, turnaround time, fabric tech, and after-order support. The best partners translate brand vision into wearable performance and deliver reliably, even when seasons get hectic. With that foundation, custom basketball uniforms become more than outfits; they become a standard teams can set and sustain over years.

Internal brand-building note

Teams that expand their identity beyond game jerseys coordinating practice kits, travel wear, and fan merch tend to create stronger communities and clearer recruiting signals. As programs evaluate their broader apparel mix, aligning design systems across categories keeps everything feeling intentional and premium. Many organizations do this by building a roadmap that rolls out upgrades over a season or two, balancing budget with impact.

In that same spirit, many athletic departments formalize standards around color contrast for maximum readability of numbers and names, considering arena lighting and broadcast environments. These small, technical decisions preserve clarity during fast play and ensure that team storytelling photographs beautifully for social media and local press.

In the middle of any redesign conversation, teams also explore foundational categories like practice gear and accessories to maintain daily consistency and brand discipline with items that see heavy use. That alignment often becomes the quiet difference between a team that looks assembled and one that looks truly united.

This is where an internal focus on bold, staple categories like custom sports apparel can tie the full ecosystem together giving athletes and supporters cohesive options that echo the uniform identity year-round.

FAQs

When did numbers first appear on basketball jerseys?

Numbers became widely adopted in the 1950s, supporting clearer player identification as the sport professionalized and league structures matured. Earlier decades experimented with letters and insignias, but standardized numbering helped officials, fans, and media track the action more easily.

What fabric technology made the biggest difference?

The shift from wool and cotton to nylon-polyester blends in the late 1930s was transformative, yielding lighter, more durable, and more breathable uniforms. That transition set the stage for modern performance meshes and four-way stretch fabrics used today across elite and grassroots basketball alike.

How did NBA suppliers influence custom design for everyone else?

Supplier eras set standards for fit, fabric, and creative direction. As Champion, Reebok, Adidas, and Nike successively outfitted NBA teams, those technologies and aesthetics filtered down, normalizing pro-grade materials and inspiring schools and clubs to expect similar customization and performance.

Why are City-inspired or special-edition jerseys significant?

They connect teams with local culture and community narratives, turning uniforms into canvases for civic pride. This approach expanded fan engagement and made each season’s jersey releases a cultural event, while encouraging grassroots teams to tell their own local stories through design.

How fast can teams receive custom uniforms today?

Many reputable providers quote approximately two to three weeks for delivery, depending on design complexity and order size. Digital configurators, integrated approvals, and sublimation help compress timelines without compromising detail or durability.

Conclusion: the enduring power of custom basketball jerseys

Custom basketball jerseys chart basketball’s rise from gym-class scrimmages to global spectacle, mirroring advances in materials, design, and cultural storytelling. From wool to engineered mesh, from hand-stitched letters to all-over sublimation, the uniform evolved into a high-performance artifact and a living emblem of identity. That dual role perform and represent explains why today’s teams invest so deeply in getting it right, and why the next great jersey will speak as clearly to the eye as it does to the heart.

For programs ready to translate history into what’s next, the path is clear: thoughtful concepts, legible typography, sustainable materials, and reliable production partners. In that balance lives the magic, a look that moves as well as it means. And in a sport defined by rhythm and resilience, that’s how custom basketball jerseys keep telling the story, season after season.

Gear Team Apparel provides design-forward, performance-built custom solutions from concept to delivery for teams that want their uniforms to play as hard as they do.