Common mistakes to avoid when ordering custom sports apparel

|

|

Tiempo de lectura 9 min

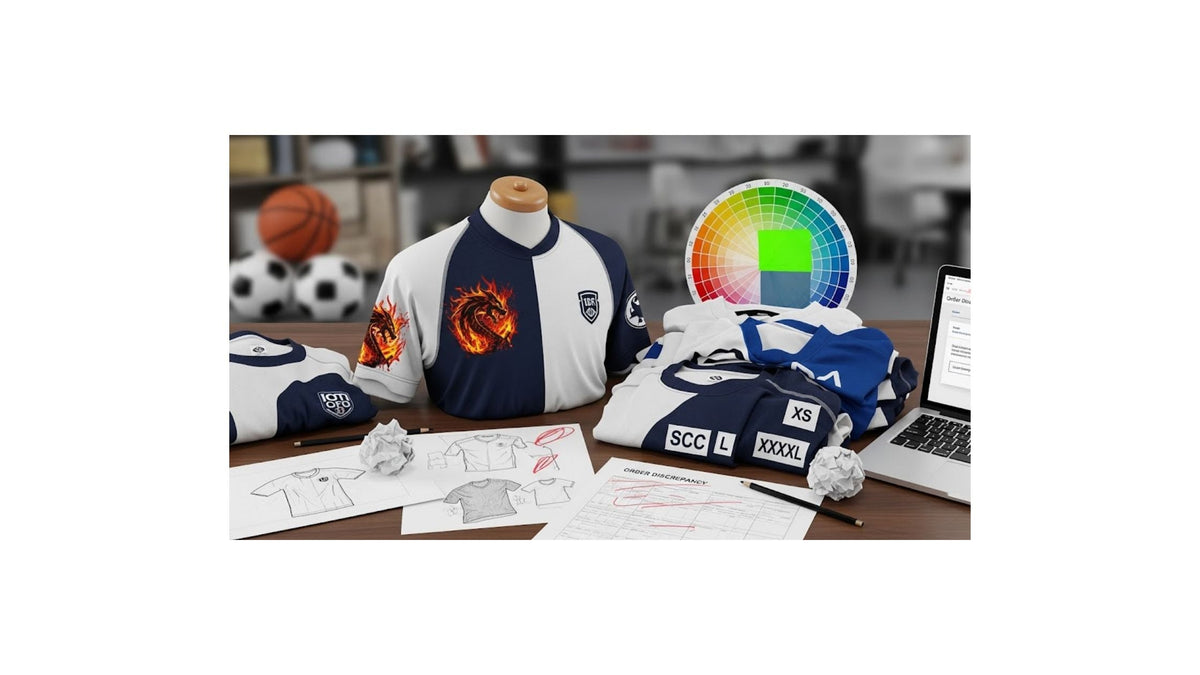

Custom sports apparel can elevate team identity, enhance performance, and strengthen fan engagement but too many buyers hit snags that waste time and budget. Teams often stumble on sizing, fabric choice, decoration methods, and vendor communication, all of which are avoidable with a smart process. As custom gear becomes a core branding pillar for teams and leagues, understanding these pitfalls pays off in on-field presence and long-term durability.

What are the most common mistakes when ordering custom sports apparel?

Custom sports apparel orders most often go wrong in five places: inaccurate sizing and fit assumptions, mismatched fabrics for the sport and climate, poor design file prep and color control, choosing the wrong decoration method for the artwork, and weak communication with manufacturers. The best antidotes include validating size runs with real samples, aligning materials to use cases, prepping print-ready vector art and Pantone colors, matching decoration to design complexity, and locking expectations in writing with your vendor.

Sizing and fit errors compound fast

Sizing charts are not universal, and a “Medium” from one manufacturer can fit like a “Large” elsewhere. Teams that skip sampling across a full size run (youth, women’s, men’s) frequently face mass returns, exchanges, and morale hits when uniforms arrive. Always test real garments on bodies that reflect your roster, note grading consistency (e.g., sleeve length, inseam, chest), and adjust your buy curve before production.

The fabric doesn’t match the sport

A slick design on the wrong fabric will underperform. Breathable, moisture-wicking polyester blends are typically ideal for high-output sports, while heavier cotton blends can feel stifling in summer heat. Order swatches, check weight (GSM), hand feel, stretch (spandex/elastane content), and colorfastness; then match fabric to environment—indoor vs. outdoor, hot vs. cold, contact vs. non-contact—before committing to bulk.

Which decoration method fits your artwork and budget?

Custom sports apparel succeeds when the decoration method matches the artwork and the garment. Complex gradients, fine detail, and all-over prints behave very differently across screen printing, embroidery, sublimation, and direct-to-garment (DTG). Choosing without understanding the tradeoffs often leads to muddy graphics, puckering fabric, or premature wear.

Method |

Best for |

Key strengths |

Common pitfalls |

Screen printing |

Solid spot colors, large front/back logos |

Vibrant color, durable, cost-effective in bulk |

Poor for tiny detail or complex gradients; color misregistration on stretchy fabric |

Embroidery |

Logos, names, caps, polos, tackle twill numbers |

Premium look, longevity, texture |

Small text gets illegible; puckering on lightweight performance knits |

Dye sublimation |

All-over designs on polyester |

Unlimited colors, breathable print, no cracking |

Limited to polyester; color shifts on non-white bases |

DTG |

Short runs, multi-color gradients on cotton |

Photographic detail, low MOQ |

Less durable than screen on heavy use; weaker color on dark synthetics |

Color, contrast, and readability are design lifelines

If fans can’t read your numbers from the stands, the design failed. Low-contrast color choices (e.g., navy on black), ultra-thin strokes, and overly ornate fonts sink legibility. Use high-contrast palettes, block numerals, and stroke weights that hold up at game distance. Print a true-size test, step back, and review on the actual garment color to catch issues before they hit press.

How do artwork files, color management, and placement go wrong?

Design files often arrive in the wrong format, color space, or resolution, which forces last-minute fixes that degrade quality. Vector artwork (AI, EPS, or PDF), outlined fonts, and linked high-resolution rasters at 300 DPI are foundational. Specify Pantone Matching System (PMS) colors for screen printing and embroidery thread charts for consistent branding, and keep production in CMYK, not RGB, to avoid unexpected shifts on press.

Placement and scale require discipline

Tiny left-chest logos that vanish or oversized center prints that buckle around seams are common. Reference vendor placement guides (e.g., center chest, full back, sleeve hits), measure from collar and side seams, and scale within recommended ranges by size. Approve digital mockups and, when possible, pre-production samples to verify alignment and balance before bulk runs.

What timelines and approvals prevent production setbacks?

Production lead times expand during peak seasons, and freight delays can stack. Teams that plan backward from game day building in time for sampling, revisions, production, and shipping avoid rush fees and compromise. Establish an approval chain: fabric/trim sign-off, color and art proof, size run sample, pre-production sample, and final production authorization, with clear accountability at each step.

Stage |

Owner |

What to approve |

Risk if skipped |

Fabric/trim sign-off |

Team |

Hand feel, weight, wicking, colorfastness |

Wrong hand or durability under game conditions |

Art/tech pack |

Designer |

Vector art, PMS, placement, numbering |

Color drift, misplacement, wrong roster details |

Size run sample |

Team |

Fit across sizes, grading consistency |

Mass misfit, returns, low morale |

Pre-production sample |

Vendor |

Exact decoration, placement, colors |

Surprises in bulk (unfixable at scale) |

Production authorization |

Team |

Final green light, timeline |

Missed deadlines, rush production errors |

Samples are not optional

Skipping samples is a false economy. A single round of physical proofs exposes fabric sheen, thread tension in embroidery, dye sublimation vibrancy, and numbering alignment you can’t reliably judge from a mockup. Allocate time and budget for samples; they are cheaper than reprints and reputational damage after a missed opener.

How vendor vetting and communication shape outcomes

Teams often choose vendors solely on unit price, ignoring quality controls, communication habits, and post-sale support. Vet partners through reviews, testimonials, and portfolio depth, and insist on written specs for materials, decoration methods, and timelines. Clear, frequent communication with visual references mood boards, annotated proofs dramatically reduces misinterpretation and costly redo's.

Lock expectations in writing

A concise statement of work should capture fabric composition, GSM, stitch type (e.g., flatlock for chafe-prone seams), decoration method, PMS colors, placements with measurements, approved size run, MOQ, unit price tiers, delivery windows, and warranty on defects. This shared source-of-truth minimizes scope creep and protects both sides when pressure rises near season start.

Sport-specific details buyers forget

Each sport punishes uniforms differently. Basketball jerseys thrive on lightweight mesh polyester, deep armholes, reinforced necklines, and heat-applied numbers that flex without cracking. Baseball uniforms need abrasion resistance for slides, double-needle stitching, and ventilation under the arms and back yoke to manage long innings in the sun. Factor in rule compliance for number sizes and placement in your league, and specify anti-odor treatments or UPF ratings for outdoor play where appropriate.

In basketball-focused orders, it’s wise to align artwork scale with camera visibility while maintaining breathability. Mid-season reorders should be planned early to maintain dye lots and thread colors across the roster. It’s also the moment to evaluate whether your team is ready to level up to performance lines that match your design system across warm-ups and travel gear, not just the game kit securing consistency from court to concourse pairs form with function.

Teams moving into baseball should stress-test fabric against clay and grass stains, assess colorfastness for repeated washing, and confirm button placket reinforcement to avoid mid-game failures. Choose tackle twill for durable names and numbers when the budget allows, and lock in PMS references for team caps to keep brand cohesion across vendors.

Budget myths and how to spend where it counts

Buyers often overspend on flashy design and underspend on the materials and methods that determine longevity. If you must compromise, preserve legibility and fabric quality first. Then adapt decoration: screen print for solid graphics, embroidery for small premium hits, or dye sublimation for complex all-over looks on polyester. A balanced spec reduces per-wear costs and keeps the team looking sharp into the postseason.

Small batch orders benefit from DTG or heat transfer vinyl for quick turnaround and minimal MOQ, while tournament-scale orders reward screen printing’s efficiency. For rosters with frequent changes, plan name/number overlays as modular components to avoid reprinting entire jerseys. Align your reorder strategy with the vendor’s minimums and lead times to prevent last-minute surcharges.

Technology and the future of customization

Advances like 3D scanning, AI-assisted recommendations, and virtual visualization are speeding up fit accuracy and design decisions. While still emerging in mainstream team orders, these tools promise better fit data, smarter fabric and color picks, and more confident approvals before production—an encouraging shift for teams seeking precision without endless sampling.

Build a reusable spec: your “tech pack”

Codify your choices in a master tech pack: brand colors (PMS), typography for names/numbers, number formats, logo clear space, decoration method by garment zone, fabric specs by sport and season, and approved placements with measurements. Reuse it across vendors and seasons to reduce variance, collapse revision cycles, and keep your identity coherent in every photo, stream, and scoreboard shot.

Mid-order checkpoints that save seasons

Create a milestone calendar anchored to opening day. Four weeks out: lock final roster, numbers, and captain patches. Three weeks: approve pre-production samples. Two weeks: production in progress—confirm transit plan and contingency shipping. One week: receive, inspect by size and player, and stage spares for inevitable last-minute scrambles. This cadence avoids the “day-before” panic that leads to accepting subpar goods.

As you inspect deliveries, spot-check stitching consistency, verify numbering and spelling against roster sheets, and test a garment through a wash cycle to ensure no color bleeding or peeling graphics. Capture any deviations with photos and timestamps, and alert your vendor immediately; documented quality issues are easier to remediate within warranty windows.

Avoiding branding pitfalls beyond the jersey

Don’t let warm-ups, shooting shirts, and coaching pools drift off-brand. Apply the same PMS, logo placement, and legibility rules across your apparel ecosystem. Sponsors will thank you for consistent exposure, and your team will project a cohesive identity from bus arrival to post-game interviews. Fans notice, camera lenses notice, and recruits notice, too.

Uniform packs should scale for weather: cold-weather layers with raglan sleeves for mobility, quarter-zips with zipper garages to protect chins, and sideline parkas sized to fit over pads for football and lacrosse. Add tear-away labels for comfort, and consider perforated or laser-cut ventilation where heat builds.

Real-world placement for sport-specific apparel

Basketball fronts favor a centered wordmark and clear block numbers; backs prioritize number visibility with optional player names above. Side panel graphics can add flair but should avoid narrow lines that break at seams. For baseball, prioritize chest script legibility and durable twill for numbers to survive slides and laundering, with cap logos matching PMS and embroidery density for crisp edges.

As you refine your basketball kit, take a moment mid-season to evaluate whether upgraded fabrics or decoration methods could improve breathability and durability for playoffs. Many programs find that elevating those finishing touches is the difference between “good enough” and gear that players are proud to wear on and off the court.

In the diamond context, reserve minimal plate hits for performance zones likely to rub against gear, and balance large back numerals with ventilation to manage heat during doubleheaders. Stitch density, thread type, and backing should be chosen to avoid stiff spots that chafe under backpacks or chest protectors.

Sport-specific links to explore

If your roster is hoops-heavy, a dedicated path for concepting and ordering makes life easier for coaches and managers. Building from proven templates helps teams move fast while keeping identity intact, especially when onboarding new players mid-season with accurate numbering and size consistency. It’s a smart moment to explore solutions tailored to custom basketball jerseys .

Programs fielding varsity and junior varsity baseball teams benefit from unified specs across both squads. A shared color system, twill style, and numbering standard simplify reorders and sponsor placements across the season. For material and decoration guidance aligned to dugout realities, it’s worth diving deeper into custom baseball jerseys .

FAQs

What should I look for when choosing a vendor for team uniforms?

Prioritize proof of quality (portfolio, samples, references), clear written specs, responsive communication, and transparent timelines and MOQs. Compare not just unit price but also sampling policies, warranty on defects, and reorder processes to keep future seasons smooth.

How far in advance should I order custom team uniforms?

Work backward from your first competition and build at least 4–6 weeks in for sampling, approvals, production, and shipping. Busy seasons can extend timelines further, so add buffers, especially for complex prints or embroidery-heavy designs.

Which printing method lasts longest for high-contact sports?

Screen printing and embroidery both offer excellent durability when matched to the correct fabric and art. For all-over graphics on polyester, dye sublimation is highly durable and breathable because the dye bonds within the fibers rather than sitting on top.

How do I prevent color mismatches between seasons?

Lock brand colors with Pantone codes, archive approved fabric swatches and thread charts, and insist on pre-production color proofs each reorder. Consistent references minimize dye lot drift and maintain a unified look across new and existing pieces.

Is custom sports team apparel worth the investment?

Well-executed custom sports team apparel strengthens identity, cohesion, and professionalism, which can boost motivation and fan engagement. When materials, decoration, and fit are chosen wisely, the per-wear value can outperform off-the-shelf options.

Conclusion

Custom sports apparel delivers identity and performance, if you avoid the classic traps of sizing, fabric mismatches, decoration misalignment, and fuzzy vendor communication. Anchor your process in samples, tech packs, PMS control, and milestone approvals to keep quality high and stress low from preseason to playoffs. When your program is ready to order with confidence, Gear Team Apparel is here to provide this service.